Description

Our this fully automated sharpening machine is engineered for precision, consistency, and unparalleled ease of use. Gone are the days of relying on skilled technicians for hours of manual labor. Our blades' sharpener integrates advanced robotics, high-resolution optical scanning, and artificial intelligence to deliver a perfect edge every time. Its sleek, fully enclosed design ensures operator safety and contains debris, while the intuitive touchscreen interface allows for seamless operation with minimal training. From the moment a dull blade is loaded onto the magnetic chuck, the system takes over: it scans the blade's profile, identifies wear patterns, selects the optimal grinding path, and executes a multi-stage sharpening process with micron-level accuracy. The result is a blade that not only meets but exceeds original equipment manufacturer (OEM) specifications, ensuring maximum productivity and longevity for your cutting tools.

Specification -HT800MM Automatic Sharpener

|

Maximum grinding length |

800mm |

|

Work area (length*width) |

800*180mm(Electromagnetic suction cup) |

|

Grinding wheel size |

200*100*32mm(can choose as your requirement) |

|

Rail |

Machine guide rail + wear-resistant strip |

|

Cutting Feed method |

manual + mechanical ratchet push rod automatic feed |

|

grinding precision |

≤0.05mm/m |

|

Operating voltage |

380v |

|

Grinding head transmission mode |

belt drive

|

|

machine tool grinding head round-trip speed |

About 14m/min |

|

Angle-adjustable grinding head |

±10° |

|

Angle-Work adjustable |

±90° |

|

Grinding head motor power |

3.0KW-1440r/min |

|

Power of lifting motor |

0.37KW |

|

Moving motor power |

0.75KW |

|

Water pump motor power |

0.04KW |

|

total power |

About:4.5KW |

|

total weight |

About:950KG |

|

Overall dimension |

About:2450*1000*1250mm |

Our Sharpener Feature

1. Adaptive Grinding Algorithm: The software dynamically adjusts feed rate, pressure, and cooling based on real-time feedback, preventing overheating and ensuring a consistent burr-free edge.

2. Multi-Axis Robotic Arm: Provides unparalleled flexibility, capable of sharpening various size of blades.

3. Centralized Coolant Filtration:A built-in cooling and filtration system extends the life of the grinding wheel and guarantees a superior surface finish on the blade.

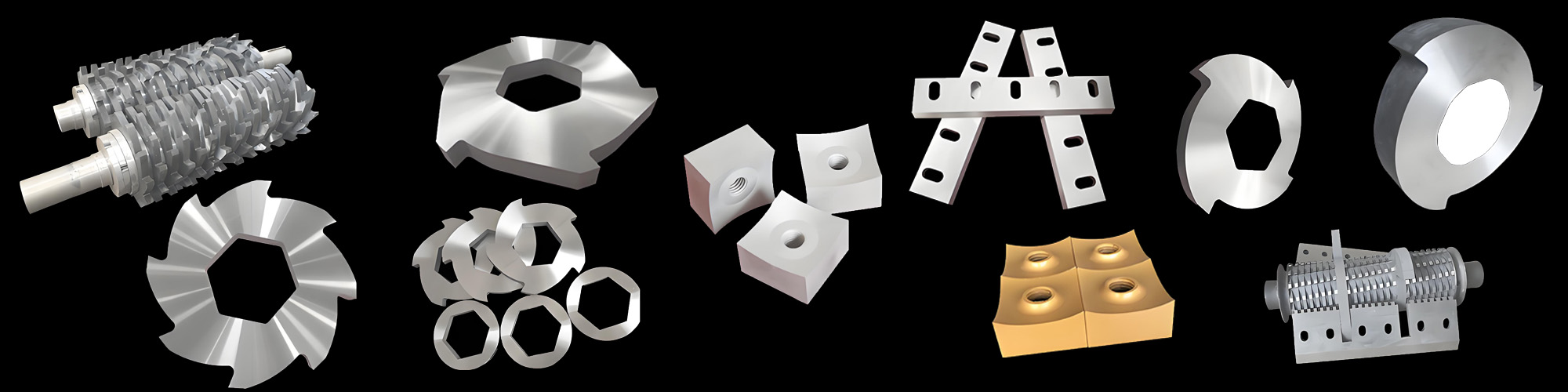

Application Range

Our Sharpener is versatile and finds critical applications across numerous industries. It is ideally suited for processing industrial blades used in plastic recycling (granulator blades), paper and printing (slitter blades), metal processing (shear blades), and food packaging (guillotine cutters). Its ability to handle various tool steels, carbide-tipped blades, and high-speed steel (HSS) makes it an indispensable asset in any maintenance workshop focused on reducing downtime and operational costs.

After-Sales Service of our Sharpener

We back our product with a comprehensive service package. This includes a standard 12-month warranty on parts and labor. Every customer receives on-site installation and operational training from our certified engineers. We offer a dedicated 24/7 technical support hotline and an online portal for spare parts ordering. Furthermore, we provide customizable service contracts for periodic preventive maintenance, software updates, and priority on-site support to ensure your investment remains at peak performance for years to come.

can not be empty

The E-mail format is not correct

can not be empty