HT2300MM Automatic Sharpener

|

Maximum grinding length |

2300mm |

|

Work area (length*width) |

2270*180mm |

|

Grinding wheel size |

200*100*32mm(can choose as your request) |

|

Rail |

Machine guide rail + wear-resistant strip |

|

Cutting Feed method |

manual + mechanical ratchet push rod automatic feed |

|

grinding precision |

≤0.05mm/m |

|

Operating voltage |

380V50HZ |

|

Machine tool grinding head reciprocating speed |

About 17m/min |

|

Angle-adjustable grinding head |

±5° |

|

Workbench adjustable angle |

±90° |

|

Grinding head transmission type |

V-belt drive |

|

Grinding head power (special grinding machine motor) |

4.0KW-1440r/min |

|

Lift motor power (specialized motor) |

0.75KW |

|

Moving motor power |

0.75KW |

|

Water pump power |

0.125KW |

|

Total power |

About 6.0KW |

|

Total weight |

About 2400KG |

|

Overall dimension |

About 4500*1200*1250mm |

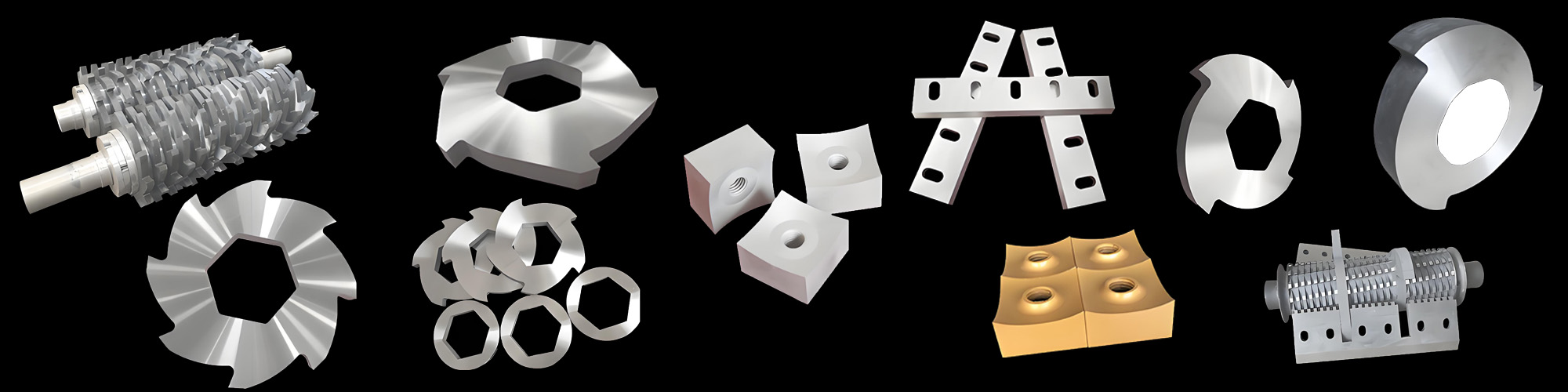

This grinding machine is an economically practical, highly durable, and user-friendly model with minimal failure rates, independently developed and manufactured by our company. It is specifically designed for dedicated knife grinding workshops, large rotary cutting plants, plywood factories, and large-scale printing and paper-cutting facilities.

The machine features a double-layer welded structure made of national standard steel plates, which has undergone vibration stress relief treatment. Equipped with a high-power electromagnetic chuck, the machine securely holds the blade in place on the worktable when the chuck is activated, eliminating the need for bolt clamping and saving time. This ensures a flatter and more precise edge during grinding. Once the blade is properly positioned, the machine automatically performs grinding wheel compensation and self-adjusts for grinding without manual intervention, reducing labor time by approximately 40 minutes.

Ideal for: large-scale processing plants, rotary cutting facilities, plywood manufacturers, and major printing and paper-cutting factories.

can not be empty

The E-mail format is not correct

can not be empty