Model No:HTDS 600

Knife box size: 600x500mm

Equipment weight: 1000KG

Motor Power:15-18.5KW

Reducer: 2sets

Blades material: 55crsi, 99CrSi, Cr12MoV, SKD-11, H13, DC53

Bearing: China brand

Power unit:2 Sets

Logo & Color: Customized

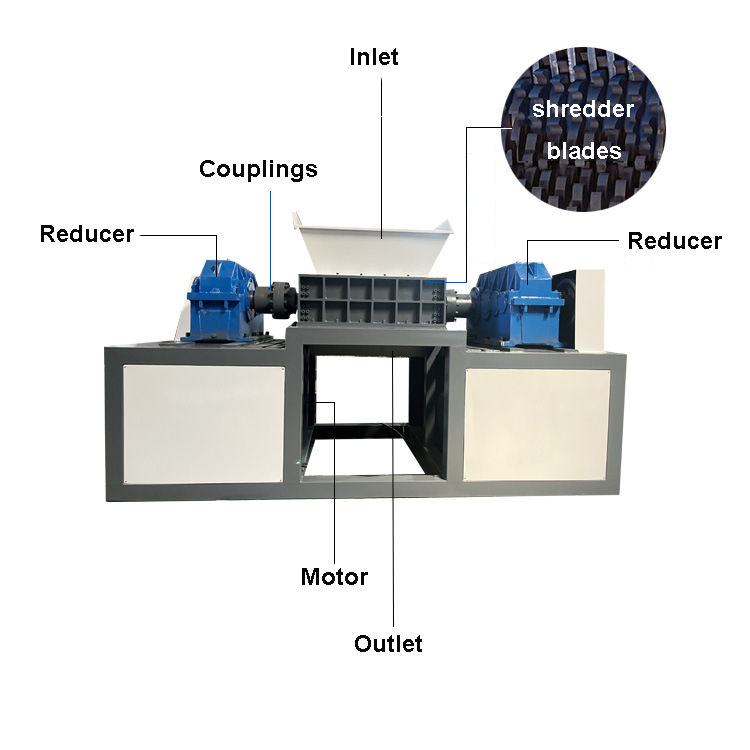

Introduction of our Double shaft shredder HT600

HUATAO Industrial Metal Shredders, for shredding a wide variety of waste materials, including scrap metal, car body, tire, auto parts, aluminium, cables, plastic, wood, paper and computer hard drives.

Specification of our Double shaft shredder HT600

Model No:HTDS 600

Knife box size: 600x500mm

Equipment weight: 1000KG

Motor Power:15-18.5KW

Reducer: 2sets

Blades material: 55crsi, 99CrSi, Cr12MoV, SKD-11, H13, DC53

Bearing: China brand

Power unit:2 Sets

Logo & Color: Customized

Features of our Double shaft shredder HT600

1. Shredder body: The main body of the equipment adopts Q-plate welding to eliminate stress/integrated machining to enhance the stability of the equipment under long-term heavy load.

Moving knife/fixed knife: The moving knife material is made of alloy tool steel forging, precision machining, multiple heat treatments and low-temperature freezing heat treatments. The overall toughness and hardness are consistent and can be reused, increasing cutting performance and service life. The fixed knife is installed in a hook-type manner to optimize the tool change function and make tool maintenance and change efficient.

2. Bearing/seal: The bearing seat adopts a split and easy-to-disassemble type, which can remove the moving knife, fixed knife, bearing and other components, making it easy to maintain and change the tool. The sealing structure blocks the contact between the broken objects and grease, and can also protect the bearings and gears when handling liquid materials.

3. Knife shaft: It is made of heavy-duty steel and reasonably cooperates with the tool to provide powerful power for cutting.

4. Frame hopper: It can be customized according to the customer's site for personalized processing and reasonably integrated into the production line for large-scale production.

5. High-efficiency motor reducer: It adopts energy-efficient standard motors, excellent standard products, and load tests are carried out before leaving the factory to ensure the stability of the power system.

6. Electrical control system: The main electrical control uses brand electrical components and control systems. The inlet and outlet conveying devices have contacts in the electrical box control, which is simple and safe to operate.

7. Multiple protection system: The shredding system has multiple protections such as mechanical and electrical, including main motor start protection, automatic feeding overload, motor card overload, automatic reversal and re-arrangement of materials to be shredded (the number of reversals is adjustable).

Noise reduction and dust reduction measures are taken into consideration in the design project to minimize external noise and dust. The noise at the equipment operation point is ≤85(DB)A.

Application Area of our Double-shaft Shredder HT600

Our shredders can be used for recycling all kinds of waste, such as municipal solid waste, solid hazardous waste, industrial production waste, waste paper shredding, wood shredding, plastic shredding, steel shredding, rubber shredding, leather shredding, home appliance shredding, pipe shredding, etc.

For shredding: metal, tires, steel drum, car body, plastic bucket, scrap clothes,wood pallet,carton box ,aluminum can, pipes, kitchen waste etc.

Click directly to send a message via WhatsApp

can not be empty

The E-mail format is not correct

can not be empty